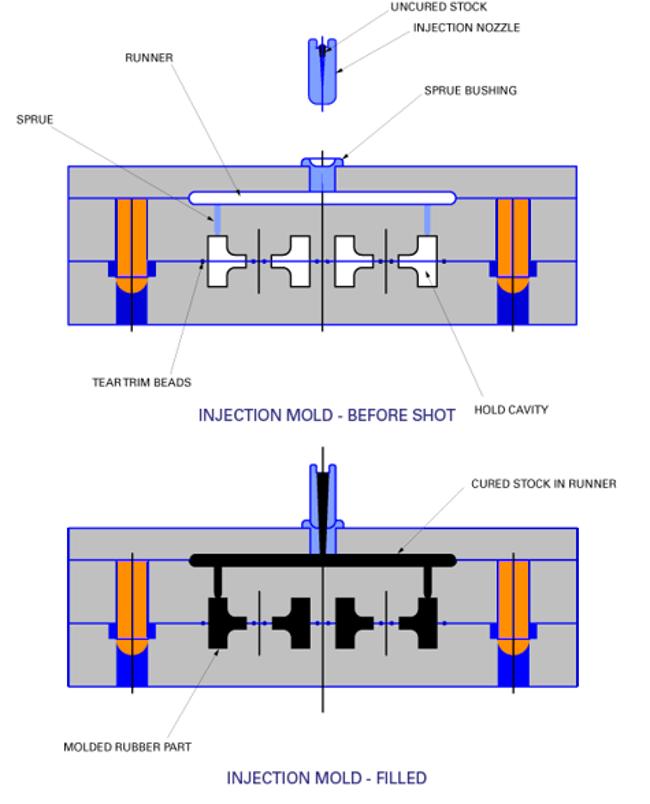

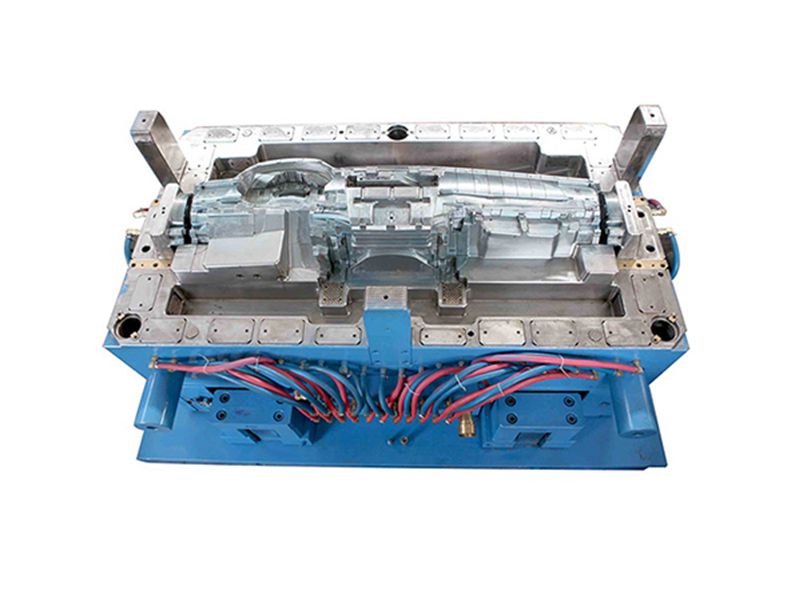

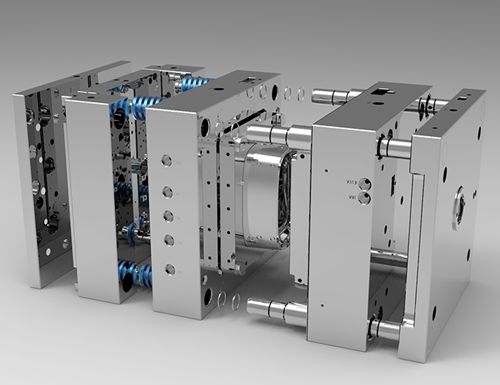

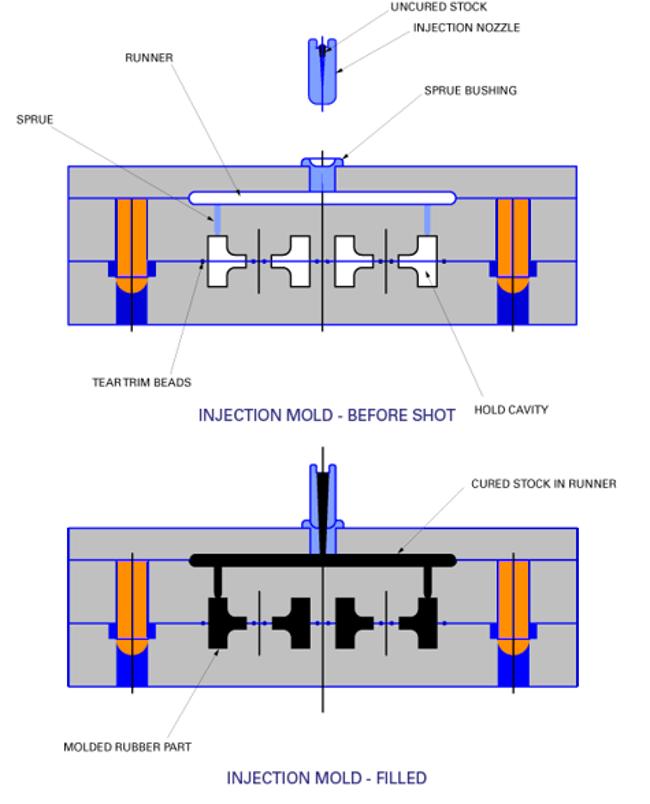

1. Rubber Injection Molding

Injection Molding is when an uncured rubber strip is fed through a screw barrel into a heated, closed mold (the mold is specific to the part and may have multiple cavities). The screw pushes a measured amount of rubber through a system of gates and runners into the cavities. The pressure of the press holds the mold closed. The rubber is held in the heated cavity for a specific amount of time to properly cure the rubber into its final shape.

ADVANTAGES

· Reduces piece price cost on mid to high volume components

· Good for high precision components

· Can accommodate over-mold or rubber bonded to metal or other material parts

· Flexibility for types of material to use

· Short cycle times

DISADVANTAGES

· Higher initial tooling cost

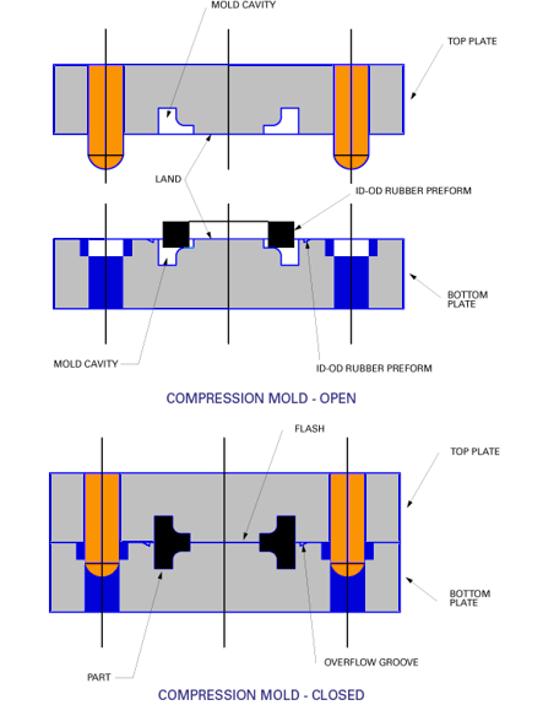

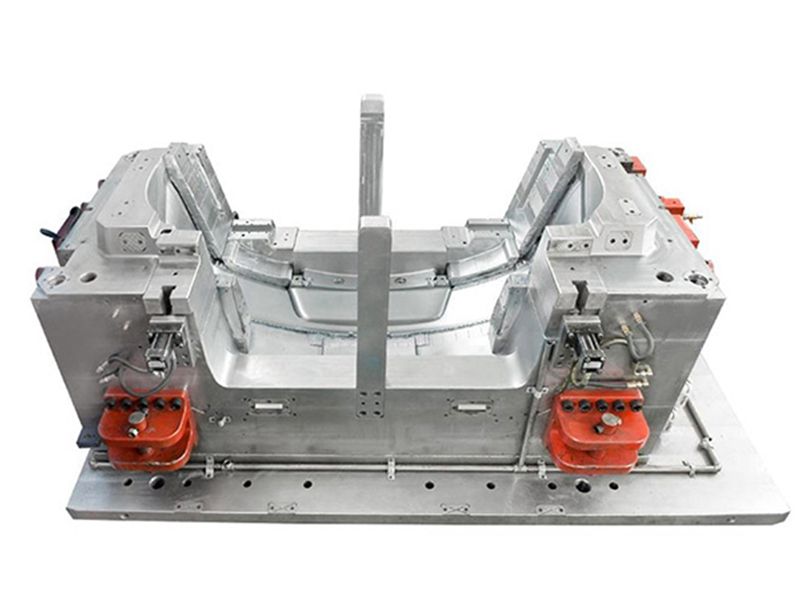

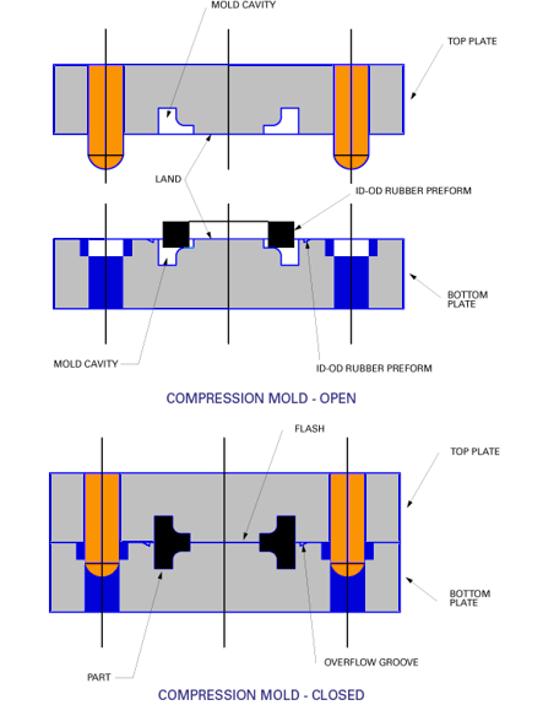

2. Rubber Compression Molding

Compression molding is when a preform (specific size and weight of uncured rubber) is placed into the open mold. The heated mold (specific to the part) is then closed using hydraulic pressure. The rubber is held in the heated cavity for a specific amount of time to properly cure the rubber into its final shape.

ADVANTAGES

· Lower initial tooling cost

· Best for low volume production

· Good for large components

· Can accommodate over-mold or rubber bonded to metal or other material parts

DISADVANTAGES

· Labor intensive compared to injection molding

· More wasted material than injection molding

· Higher cycle time

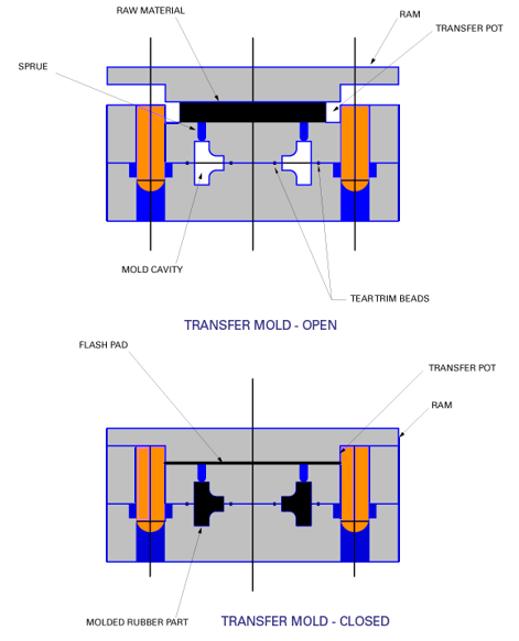

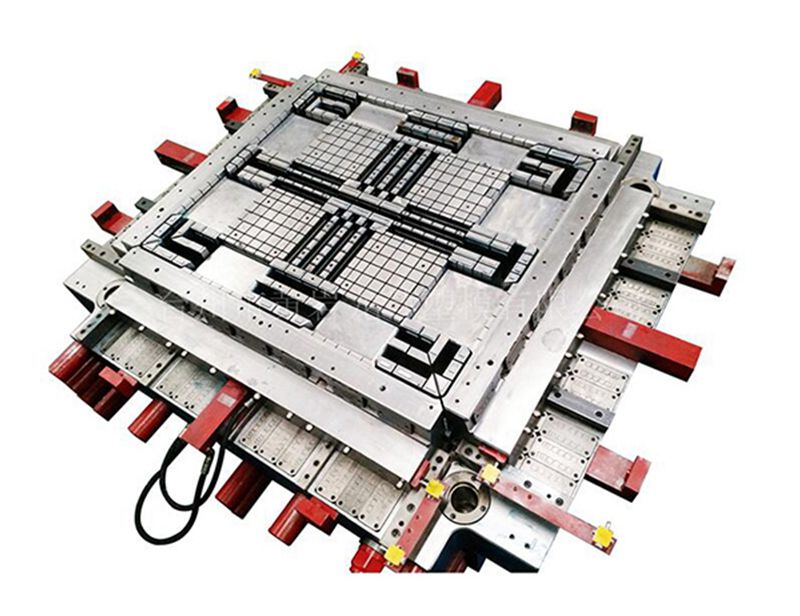

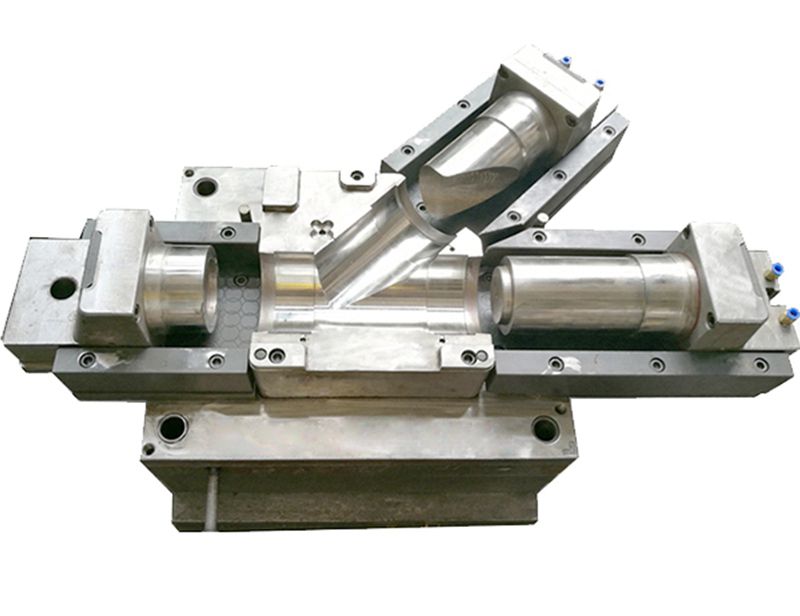

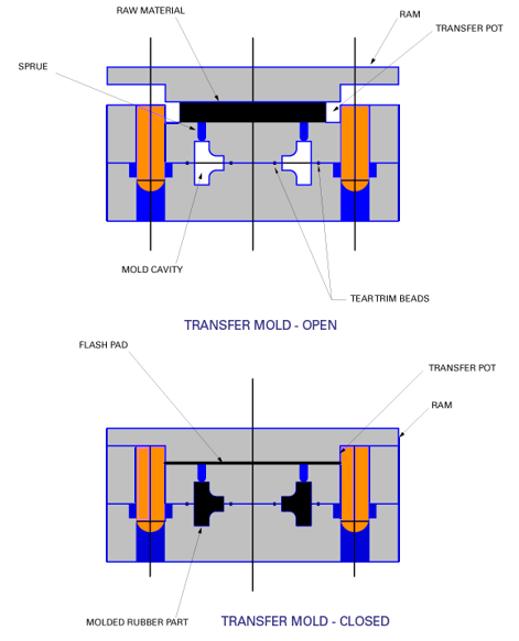

3. Rubber Transfer Molding

Transfer Molding is molding is when a preform (specific size and weight of uncured rubber) is placed into the transfer pot. The ram is then closed pushing the uncured rubber through the runner and gate system into the part cavity. The pressure of the press holds the mold closed. The rubber is held in the heated cavity for a specific amount of time to properly cure the rubber into its final shape.

ADVANTAGES

· Good for high precision applications

· Can accommodate over-mold or rubber bonded to metal or other material parts

· Good for colored compounds of rubber

DISADVANTAGES

· Labor intensive compared to injection molding

· Higher tooling costs than compression tools

Reference:

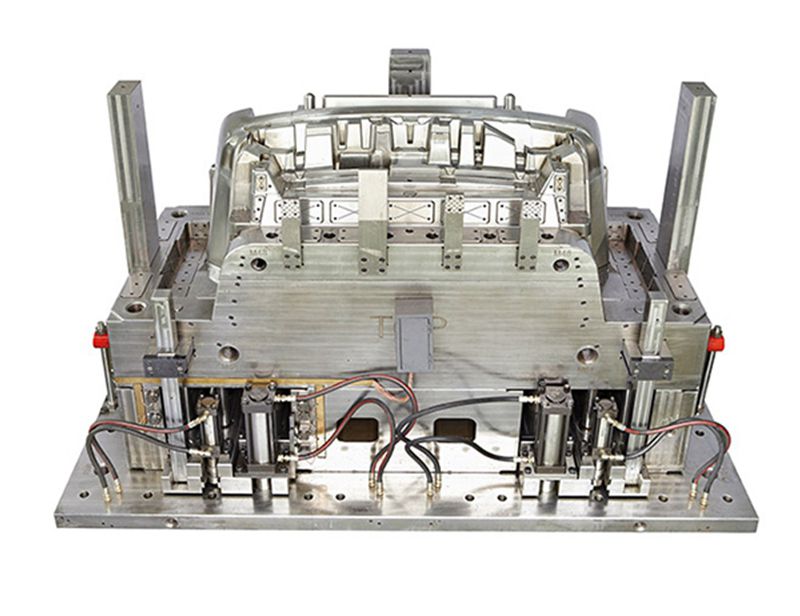

Better bright silicone rubber & plastic mould products limited.