In the Field of Organic Silicon, downstream physical silicon rubber materials can be divided into solid and liquid materials, and both materials are currently widely used in various major industries, such as potting glass glue, organic silicone water, and sealing silicon Rubber products, electronic sealing accessories, etc. There are many similarities between their application fields and material properties, and their production processes are different. In the field of products, their roles and functions are basically the same. What are the differences between materials and products?

The main difference between liquid silica gel and solid silica gel is: one is liquid and the other is solid; but after processing the finished product, the two are not so easy to distinguish. Liquid silica gel is liquid and has fluidity. Solid silica gel is solid and has no fluidity.

Different fields of use

(1) Liquid silicone is generally used in baby products, silicone kitchen products and medical products, it can directly contact food and human body;

(2) Solid silica gel is generally used for daily necessities, industrial miscellaneous parts and auto parts;

(3) Safety of liquid silica gel and solid silica gel: Liquid silica gel is a highly transparent, high-safety food-grade material. No auxiliary materials such as vulcanizing agent are added during the molding process. The sealing material is formed by sealing.

Solid silica gel is a translucent material. Vulcanization is needed to accelerate the curing time.

Molding:

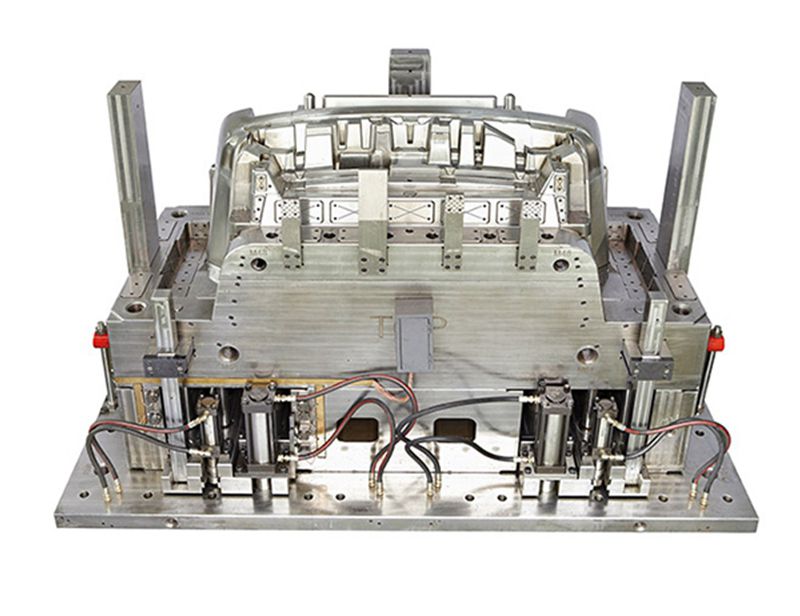

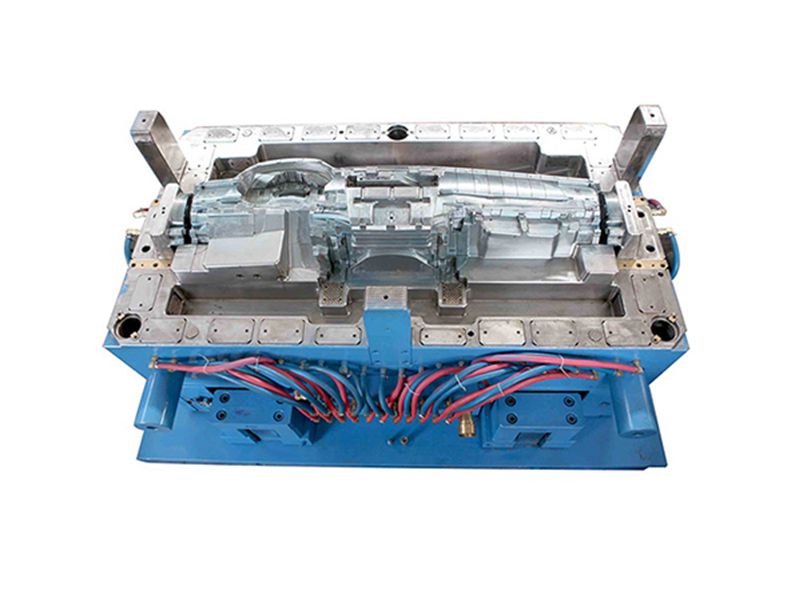

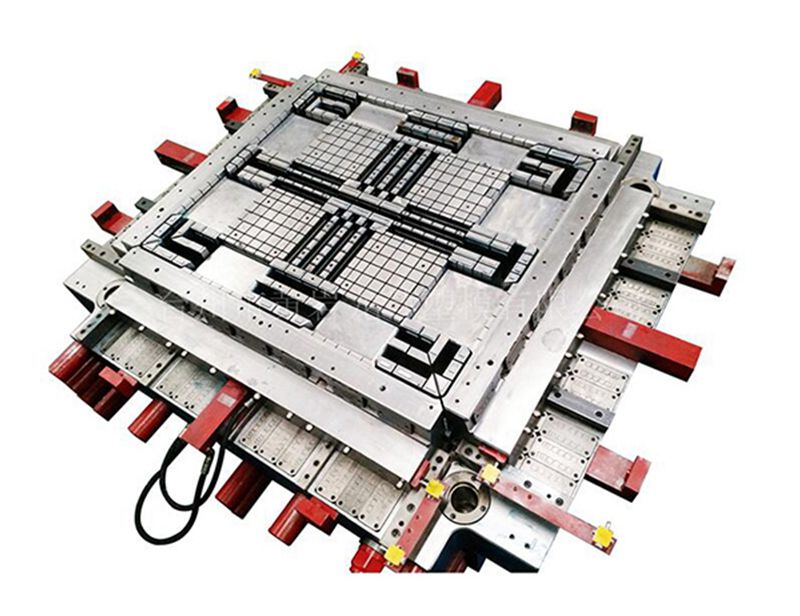

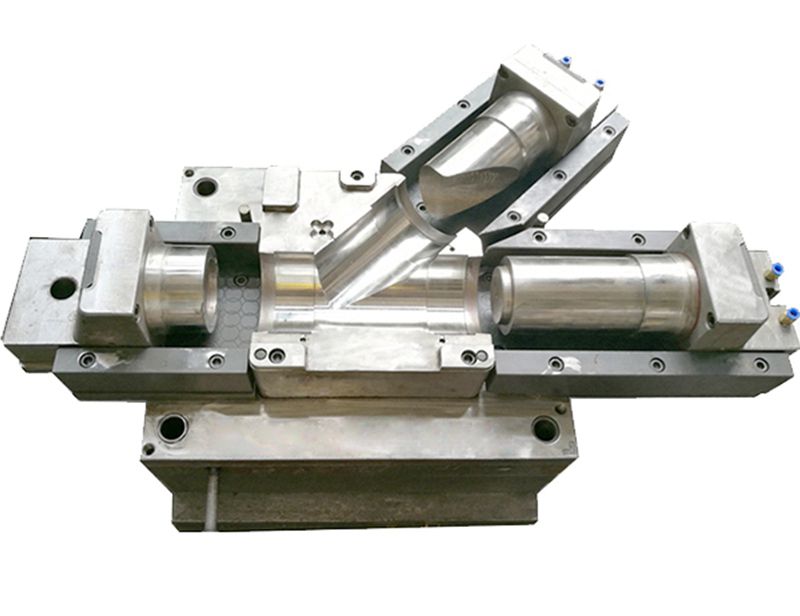

Liquid Silicone (LSR): The full name is injection molding liquid silicone rubber, and the vulcanization equipment is an injection molding machine. The injection molding machine process is very simple, the product precision is high, and the output is high (the A/B glue is mixed for a few seconds at a certain temperature). The materials are mixed and added with color glue and catalyst to automatically inject into the mold cavity without manual operation. Product advantages The product has good fluidity, strong stretch and resilience, and the mold is combined injection molding, so the product has a plastic injection port and basically no surface parting lines.

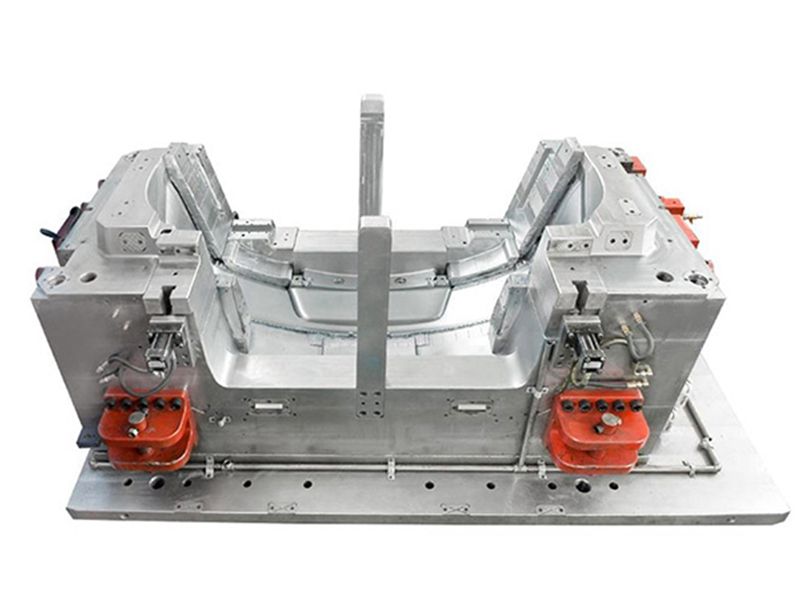

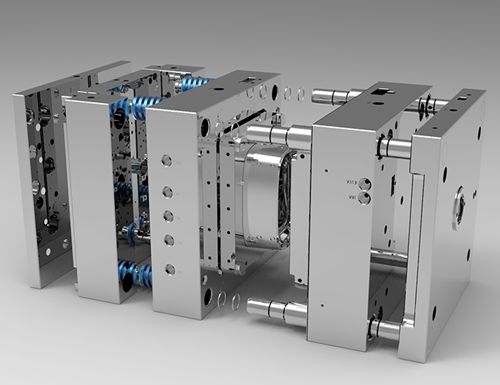

Solid Silicone: The raw material for solid silica gel molding is a solid. After the silicone rubber product manufacturer is mixed by a mixer, it needs to add color glue and catalyst, and then cut it into an appropriate size and manually put it into the mold cavity to form and cure. The automatic processing method requires manual operation to take the mold and discharge the material. Because the material is solid, the fluidity and stretch resilience are slightly lower than that of the liquid. The product has no injection port, and the processed finished product will have upper and lower parting lines.